We are professional Ring Dies,Pellet Dies,Flat dies,Feed Mill Pellet Ring Dies,Pellet Mill Ring Dies,Animal Feed Pellet Mill Ring Die,Pellet Machine Ring die,Pellet Press Ring Die,Wood Pellet Machine Ring Die Factory from china.

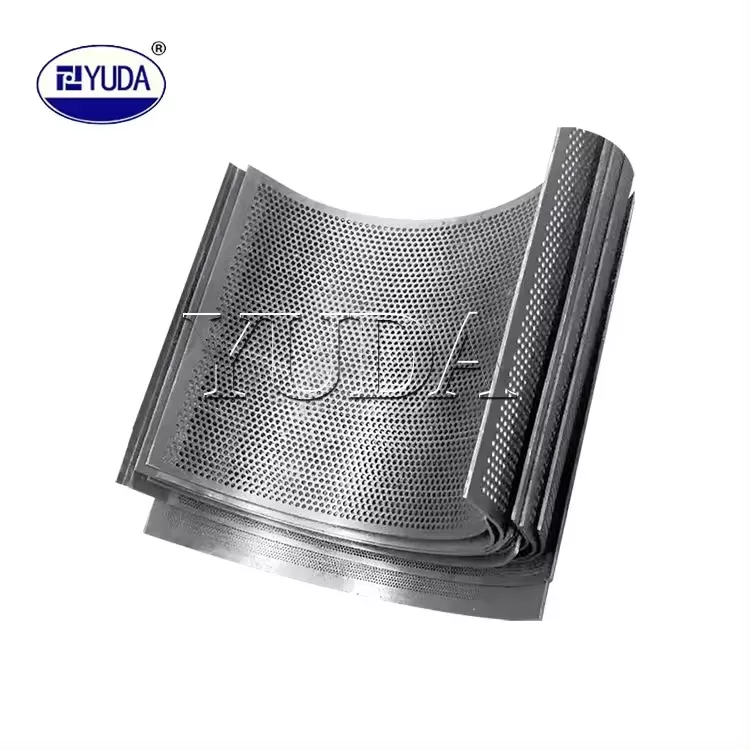

Ring die is very important part of ring die pellet machine in the whole manufacturing process. The quality of ring die not only directly relates with the quality and output of pellets, but also the running state of equipment and maintenance cost.

Applicable for Biomass pellet machine: wood pellet mill, sawdust pellet mill, grass pellet mill, straw pellet mill, crop stalk pellet machine, alfalfa pellet mill etc.

Applicable for Fertilizer pellet machine, animal feed pellet machine too.

1. Material of the ring die:

X46Cr13 (stainless steel), 20MnCr5/20CrMnTi (alloy steel)

2. Hardness of ring dies:

HRC54-60.

3. Diameter of ring die can do:

1,0mm up to 14mm

4. pellet die type can do:

Ring Die or Flat Die

5. Outer diameter can do:

Outer diameter up to 1500mm

6. Pellet Die model we can customize:

CPM, Buhler, Zhengchang, Amandus Kahl, Muyang, PTN, Andritz Sprout, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promill; etc. We can customize for you according to your drawing.

For pellet mill: SZLH250, SZLH300,SZLH320,SZLH350,SZLH400,SZLH420,SZLH508, SZLH678, SZLH768, etc

Pellet ring dies must resist abrasion, corrosion from chemical exposure and breakage caused by the physical stresses of pellet formation. The optimum die combines high resistance to abrasion, breakage and corrosion with maximum productivity.

Our expertise enables us to precisely match the die specification to your required formulation, even if it means customizing a die pattern to meet your exact needs.

Advantages of LYWF ring dies:

1. 20 years of experience in ring die production

2. High chromium high carbon content steels

3. Extremely precise manufacture

4. Advanced imported equipment

5. High hardness after heat treatment

6. Rapid delivery times

7. Test and control before shipment

8. Long service time

Compression Ratio of Ring Die

Generally speaking, the higher the compression ratio, the denser the finished pellets. But it does not mean that the higher the compression ratio, the better the pellet quality.

Compression ratio should be calculated based on raw material for making pellets and type of feed.

With many years pellet die manufacturing and research experience of WEIFENG Company, we provide some general data of ring die's compression ratio for your reference:

Buyers can customize dies with different hole diameter and compression ratio, according to different situation and requirement.

| Hole Diameter(mm) | Compression Ratio | |

| Ring die for animal feed pellet machine | ||

| Poultry&livestock feed | 2.5 - 4 | 1:4-1:11 |

| Fish feed | 2.0 - 2.5 | 1:12-1:14 |

| Shrimp feed | 0.4 - 1.8 | 1:18-1:25 |

| Ring die for biomass pellet machine | ||

| 6.0 - 8.0 | 1:5-1:8 |

The most common structure of die hole are straight hole; release stepped hole; external conical hole and internal conical hole, etc. Different die holes structure are suitable for different raw material and feed formula for making pellets.

Comment